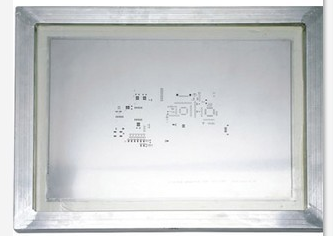

Stencil

PCB stencil is very important. In the process of PCB Assembly, the printing quality of PCB solder paste stencil will directly affect the processing quality of SMT, and the quality of solder paste printing is directly related to the quality of PCB stencil, so the correct design SMT stencil, the selection of the appropriate PCB stencil thickness and the design opening size of the PCB stencil, will be the key to ensuring the printing quality of the solder paste.

The key factors that affect the quality of PCB stencil are PCB stencil material and PCB stencil thickness, PCB stencil opening type, PCB stencil size, PCB stencil wall flatness. Therefore, in the PCB stencil design, Processing, inspection, and production process must pay special attention to PCB stencil.

PCB stencil has SMT stencil, etching stencil, and laser stencil,we always use laser stencil.

Laser Stencil

Laser Stencil is currently the most commonly used template in the SMT Stencil industry. Laser Stencil features:

Direct use of data files to make, reduce the production error link; SMT Template Opening Position Accuracy is Extremely High: Whole Range Error < 4 μ M; The opening of the SMT template has a geometry which facilitates the printing of the solder paste.

PCB and data files are required to make laser Stencil.

PCB data must be edited correctly without distortion, damage, or fracture.

The acceptable data files include GERBER, HPGL, JOB, PCB, GWK, CWK, PWK, DXF, PDF, PAD2000, POWER PCB, GCCAM4, PROTEL, AUTOCADR14 (2000), CLIENT98, CAW350W, V2001. The data must contain SMT solder paste layer as well as character layer data to check for positive and negative sides of the data, component categories, and so on.

Disadvantages of laser Stencil: Cutting one by one makes it slower.

The manufacturing process of PCB stencil has a great influence on the printing quality of the solder paste. Which PCB stencil to use depends on the product characteristics, size of welded terminals, component type, and component distribution of components on the PCB board.

FuLin is a one-stop service company specializing in PCB manufacture, PCBA contractor materials, SMT patch processing. We have many years of experience in electronic processing, advanced production equipment, and a perfect after-sales service system, which can provide you with high-quality electronic manufacturing services.

PCB ASSEMBLY

Contact Us

Tel: +86-0755-23084786

E-mail: sales@flcircuits.com

Skype: +86-18902438891

Add: Building 7th, Gangtou Industry District, Shajing Town, Baoan Dist.Shenzhen, China

Skype Chat

Skype Chat Mail inquiry

Mail inquiry